Why You Should Be Using Low Temperature Data Cables In Winter

November 17, 2022 10:49 pm Leave your thoughts

Building a custom home or office over the winter months? Your wasting your money if your using this in your project.

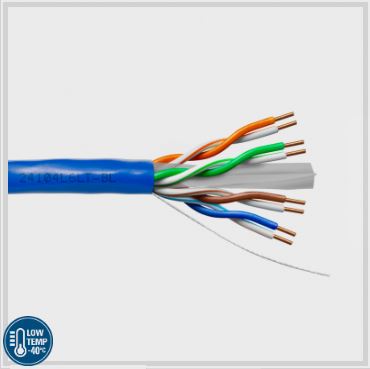

As the temperature begins to drop in cold climates many builders and home owners don’t realize the danger that poses to low voltage cable. SASA explains the benefits of using the right product in cold weather, but few people know the science behind it. Low temperature data cables are vital for two main reasons: first, standard low voltage cable jackets will crack in cold temperatures, making the cable useless; and second, the insulation on low temperature data cables is specifically designed to maintain flexibility in freezing weather.

How Standard Cable is Damaged by Cold Weather

The most common type of damage that occurs to standard cable in cold weather is cracking of the jacket. The material that makes up the jacket, called polyvinyl chloride (PVC), becomes brittle and cracks when exposed to cold temperatures. This damage can occur even if the PVC is only exposed to cold air for a short period of time. Roughing in the low voltage wiring for your custom home or office over the winter months requires pulling the cables through walls and ceilings causes tension on the cable, when the cable is very stiff due to the cold weather (around 5 degrees and below) the cables are at high risk of cracking causing the copper inside to touch which causes a short on the line.

Once the jacket cracks, the chance of a short caused by the exposed cables inside touching, drastically increases. This will result in intermittent connectivity on the line or a complete short rendering the cable and the money spent running the cables useless.

What Makes Low Temperature Data Cables Different?

Low temperature data cables are designed to withstand colder temperatures without sustaining damage. The jackets on these cables are made from a material called thermoplastic elastomer (TPE), which remains flexible even in freezing weather. This flexibility prevents cracking, even when the TPE is exposed to cold air for extended periods of time.

In addition, the insulation on low temperature data cables is also specifically designed to maintain flexibility in freezing weather. This flexibility prevents cracking and helps keep water out of the cable, even if it becomes exposed to snow or ice. As a result, low temperature data cables are much less likely to sustain damage in winter weather than standard cables.

Low temperature data cables are an important part of any winter weather building project. By using these cables, you can avoid damage to your standard cables and reduce the risk of shorts and dead cables, which can cause much bigger problems later when your project is complete and there is no way to run a replacement cable without damaging finished walls and high labour costs.

SASA offers many different solutions in the realm of whole home integration, and Control4 is just one of the many world-renowned manufacturers with whom we partner.

Regardless of the size of your project or budget, from Toronto to Oakville to King, and everywhere in between, call SASA to learn about “brilliant” solutions for your home.

Tags: Control4, Home Automation, low voltage cable, SASACategorised in: Home Automation, Products

This post was written by Mark.K